Move the flask from side to side until the investment disperses and the metal casting is revealed. Remove it with tongs and submerge it in a metal bucket of cold water.

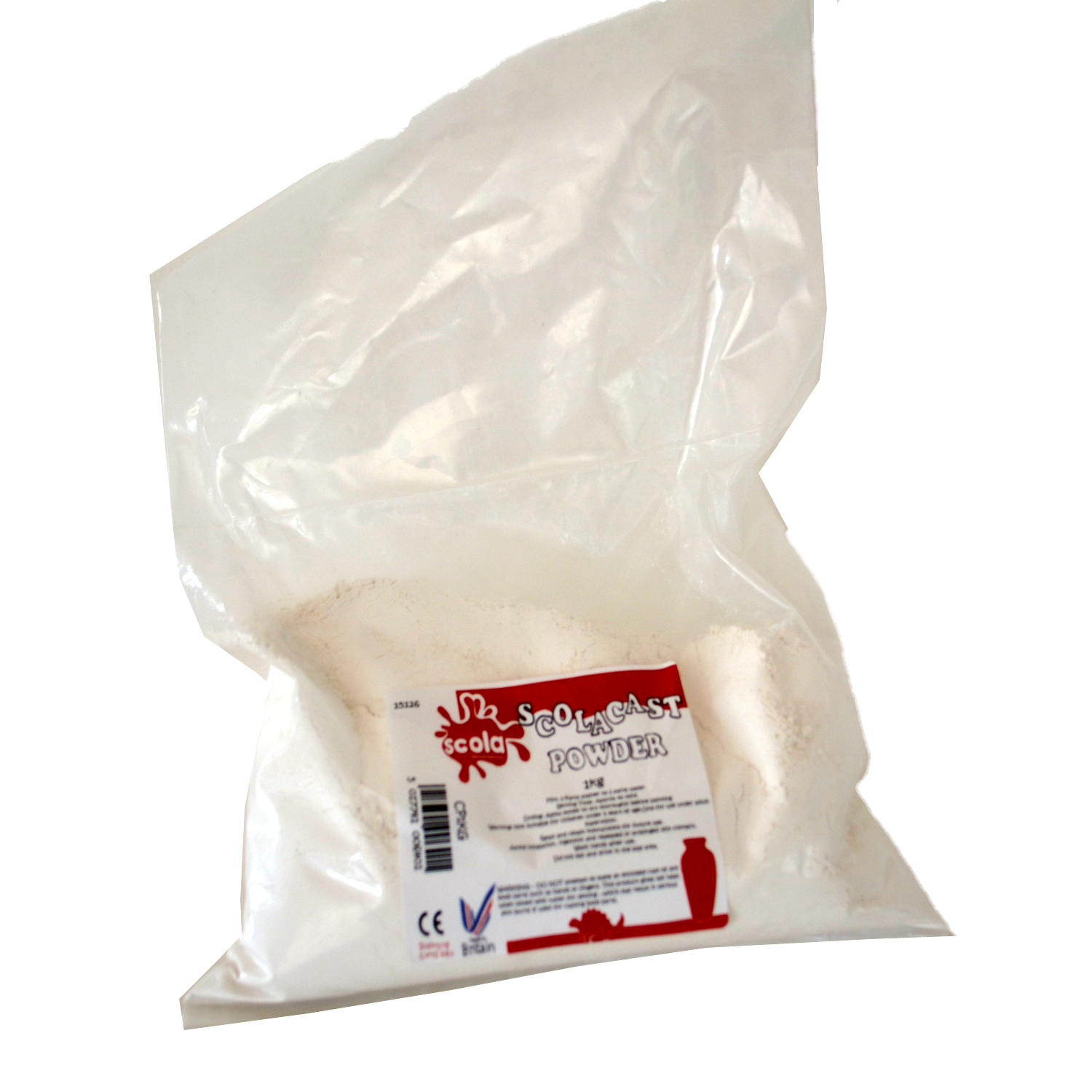

Then put it in the centrifugal machine and make sure that the crucible is closed up and is totally secured to the sprue end of the flask. Take the flask out from the kiln with a pair of large steel tongs. Once you’ve put on your protective gloves.To compensate for the sprue, add 10g of silver. Grab a pinch of powdered flux, then sprinkle over the top. Remove any existing solder, and cut any scrap pieces, so they all fit comfortably. Put the required amount of silver in the crucible.Carry out these steps to complete the lost wax casting process: Centrifugal CastingĪnd now, for the final stage in the process, centrifugal casting. The varying temperatures ensure that the investment is fully dry and hardened and the wax is thoroughly melted. To finish, increase the temperature to 720☌ and hold for another hour. After the hour has passed, turn the heat up to 400☌ for an hour and 30 minutes. Set the kiln between 150 and 200☌ and leave for an hour. With the sprue at the bottom, place the flask in the kiln to allow the melted wax to get out. Leave the flask to dry overnight – then peel away the rubber base where you will find the wax sprue.For roughly a minute or so, place the flask on the vibrating table to let any trapped air rise to the surface during the pouring.Then, squeeze the sides of the bowl as you pour the mixture into the flask. Keep a firm hold of the bowl and let as many air bubbles rise to the surface as you can. After you’ve given the mixture a good stir, put the rubber bowl on a vibrating plate.Once the powder has floated to the top of the bowl, mix for about 10 minutes to ensure the removal of air bubbles – any longer, and the mixture will become too thick to work with.Remember, it will sink to the bottom, to begin with, then rise to the top once the correct amount of powder has been added. Next, weigh up the amount of investment powder you think you’ll need and sprinkle a tablespoon of it over the water.Once done, pour the water into a rubber bowl. Then, fill the flask with water until approximately 5mm from the top. Ensure the flask is attached to its rubber base and that the ring and sprue are securely attached.Follow these instructions to find out what to do next: Be ready to move onto the next step in the process – the investment. Now you’ve completed the first few steps in the lost wax casting technique. After calculating how much silver is needed, fix the ring and the sprue to the bottom of the flask – with a gap of at least 5mm between the edges and the top of the flask and the ring.To calculate the amount of silver you need, consult these equations: for silver – calculate the weight of the wax multiplied by 11 and 10g to accommodate for the weight of the sprue. Weigh the ring and make a note of how much it weighs.To do so, hold the sprue over a low flame until it starts to drip, and then quickly place it on the ring in the heaviest area. Once the wax has been filed to your requirements, it’s time to attach a wax sprue to the ring.Top tip: remember that you can file the wax down quite thin as silver weighs 11 times more than wax. Next, file the wax to the shape you require using a special carving file.Then, outline the pattern on the ring with a scribe to guide where the first cuts will be. Using a wax tube, cut out the shape of a standard ring.Interested in giving it a go yourself? Follow our lost wax casting process steps below to find out how: The most common metals used for this process are silver, gold, brass, and bronze – so there are many opportunities for your jewelry-making projects! Lost Wax Casting Process for Jewelry Throughout the years, the lost wax casting process hasn’t just been used for jewelry, and it was also used to make sculptures and ornaments.Īlso, one of the main advantages of lost wax casting is that you can replicate the same model as many times as you’d like.

Lost wax casting, also known as cire perdue, is an ancient process where metal alloys are made into a design from a wax mold. Let us learn about The Jewelry Casting Process: Lost-Wax Casting.

Having been lost and rediscovered many times throughout history, the lost wax casting process is still used today for casting metal alloys. One of the oldest jewelry-making methods, lost wax casting, dates back to the 3rd century BC.

0 kommentar(er)

0 kommentar(er)